Buildingo -An In-Depth Guide by Buildingo.in

🔍 Introduction

Cement is not just a binding material; it’s the backbone of the infrastructure that defines the modern world. From towering skyscrapers and highways to underwater structures and smart cities, cement plays a central role.

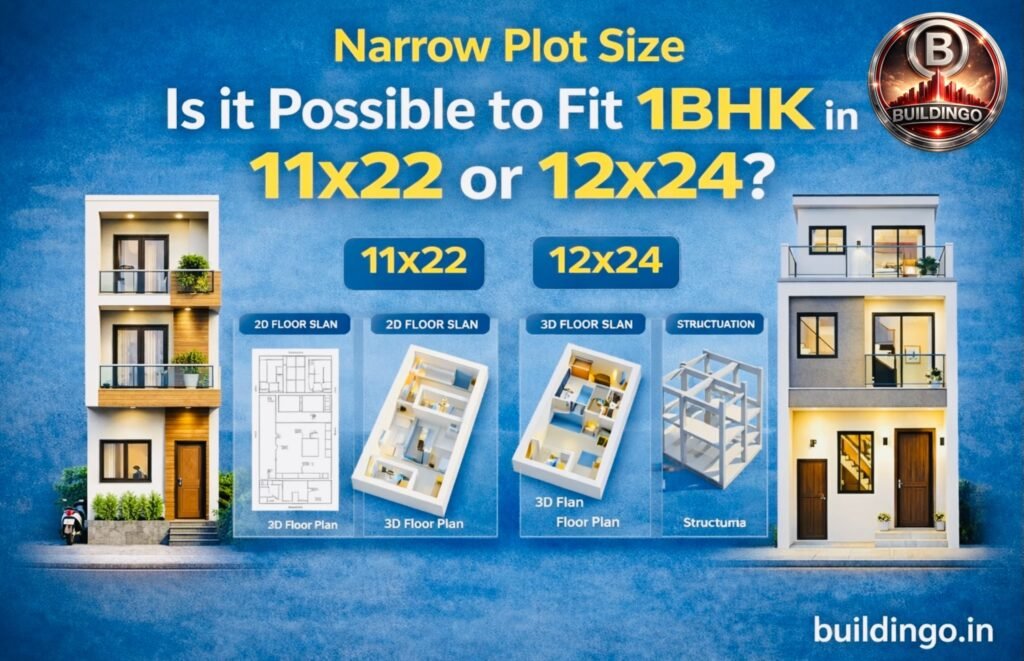

At Buildingo.in, we believe in demystifying building materials and pushing the frontiers of construction technology. Here’s a comprehensive guide on cement types, uses, advantages, future tech, and our vision in cement R&D.

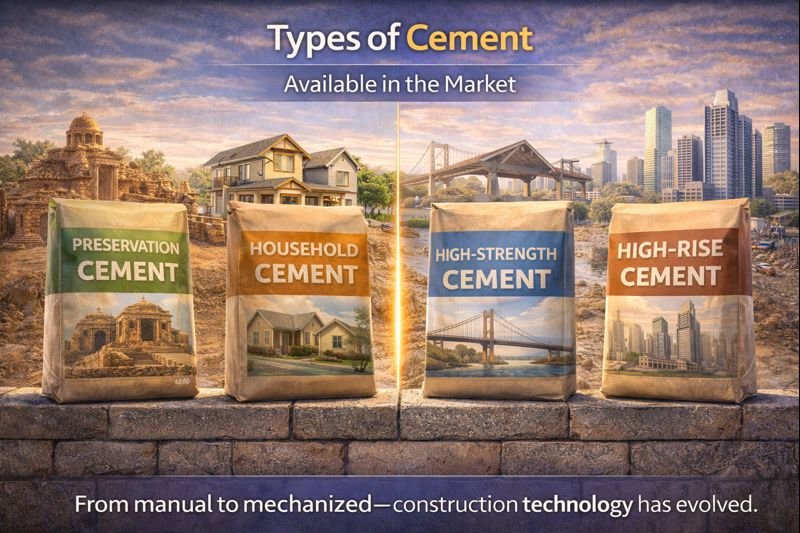

🧱 Types of Cement & Their Applications

| Cement Type | 🔧 Description | 🏗️ Applications |

|---|---|---|

| 1. Ordinary Portland Cement (OPC) | Most common; available in 33, 43, and 53 grades | Residential buildings, bridges, pavements |

| 2. Portland Pozzolana Cement (PPC) | Contains fly ash or volcanic ash; slower setting | Marine works, sewage pipes, dams |

| 3. Rapid Hardening Cement | Higher early strength gain | Road repairs, precast structures |

| 4. Sulfate Resisting Cement | Resists sulfate attacks | Foundations in soil/water with high sulfate |

| 5. Quick Setting Cement | Sets faster in moist conditions | Underwater construction, cold weather zones |

| 6. Low Heat Cement | Generates less heat during hydration | Massive concrete works like dams |

| 7. White Cement | Decorative and aesthetic applications | Flooring, wall tiles, artistic structures |

| 8. High Alumina Cement | High strength and resistant to chemical attacks | Chemical plants, refractory works |

| 9. Expansive Cement | Expands slightly after setting | Grouting anchor bolts, repairing cracks |

🏛️ Why Cement Is Superior to Historical Materials

| Historical Material | ⚠️ Limitations | ✅ Cement Advantages |

|---|---|---|

| Lime Mortar | Slow setting, weak in strength | Faster curing, high compressive strength |

| Clay Bricks & Mud | Poor durability and erosion | Resistant to weathering and wear |

| Bitumen | Not suitable for structural use | Cement has structural integrity |

| Timber Structures | Flammable and pest-prone | Fire-resistant and pest-proof |

✅ Cement revolutionized construction by providing a versatile, scalable, and durable solution for structural demands previously unmet by historical materials.

🔬 Future Technologies That Could Replace Cement

- 🧪 Geopolymer Cement

- Made from industrial waste (fly ash, slag)

- Up to 80% less CO₂ emissions

- Ultra-durable & resistant to acids and fire

- 🌱 Bio-Cement

- Made using bacteria to precipitate calcium carbonate

- Self-healing cracks

- Sustainable and biodegradable

- 🌍 Carbon-Negative Cement

- Uses mineral carbonation

- Absorbs CO₂ from the environment over time

- Ideal for green infrastructure

- 🪨 Magnesium-Based Cements

- Lower calcination temperatures

- Faster strength gain

- Used in modular and pre-fab construction

♻️ Alternatives to Cement in Specific Applications

| Alternative | Best For | Eco Benefit |

|---|---|---|

| Hempcrete | Low-rise walls, insulation | Carbon-negative, biodegradable |

| Ferrock | Structural elements | Absorbs CO₂, stronger than concrete |

| AshCrete | Road base, foundations | Made from fly ash |

| Ram Earth | Earth structures, aesthetic walls | Zero cement use, highly sustainable |

| Recycled Plastic Concrete | Paving, insulation | Reduces plastic waste |

🌐 Future of Cement in a Sustainable World

Despite emerging technologies, cement will remain integral to global infrastructure for decades. However, its future will pivot around:

- 🌿 Decarbonization technologies

- 🧠 Smart cement with sensors

- 🔁 Recyclable cementitious composites

- 🏗️ Modular & prefabricated concrete systems

- 💧 Water-efficient curing innovations

🚀 Buildingo.in’s Role in Cement Innovation

At Buildingo.in, we aim to lead the transformation of the cement industry through:

🔍 1. R&D Partnerships

- Collaborate with universities, research labs, and manufacturers

- Promote eco-friendly cement formulations

- Support geopolymer and bio-cement trials

🧑🏫 2. Educational Outreach

- Host webinars & workshops for civil engineers, architects, and builders

- Publish open-access whitepapers on material science

📊 3. Data-Driven Decision Support

- Use AI tools to recommend optimal cement types for specific conditions

- Offer lifecycle analysis and sustainability scores for cement brands

🌍 4. Sustainable Procurement Platform

- Curate eco-certified cement suppliers

- Encourage use of alternative cements and low-carbon options

🧪 5. Buildingo Labs™: Cement Testbeds

- Test, compare, and showcase next-gen cement products in real-world conditions

- Track strength, heat, emissions, and cost efficiency

🎯 Conclusion: Cement Beyond Concrete

Cement is evolving. It’s not just about strength—it’s about intelligence, sustainability, and adaptability.

At Buildingo.in, we see ourselves not just as a construction platform, but as a catalyst for a greener, stronger, and smarter cement industry.- Buildingo.